Willkommen im Fachgebiet Mikro- und Feingeräte

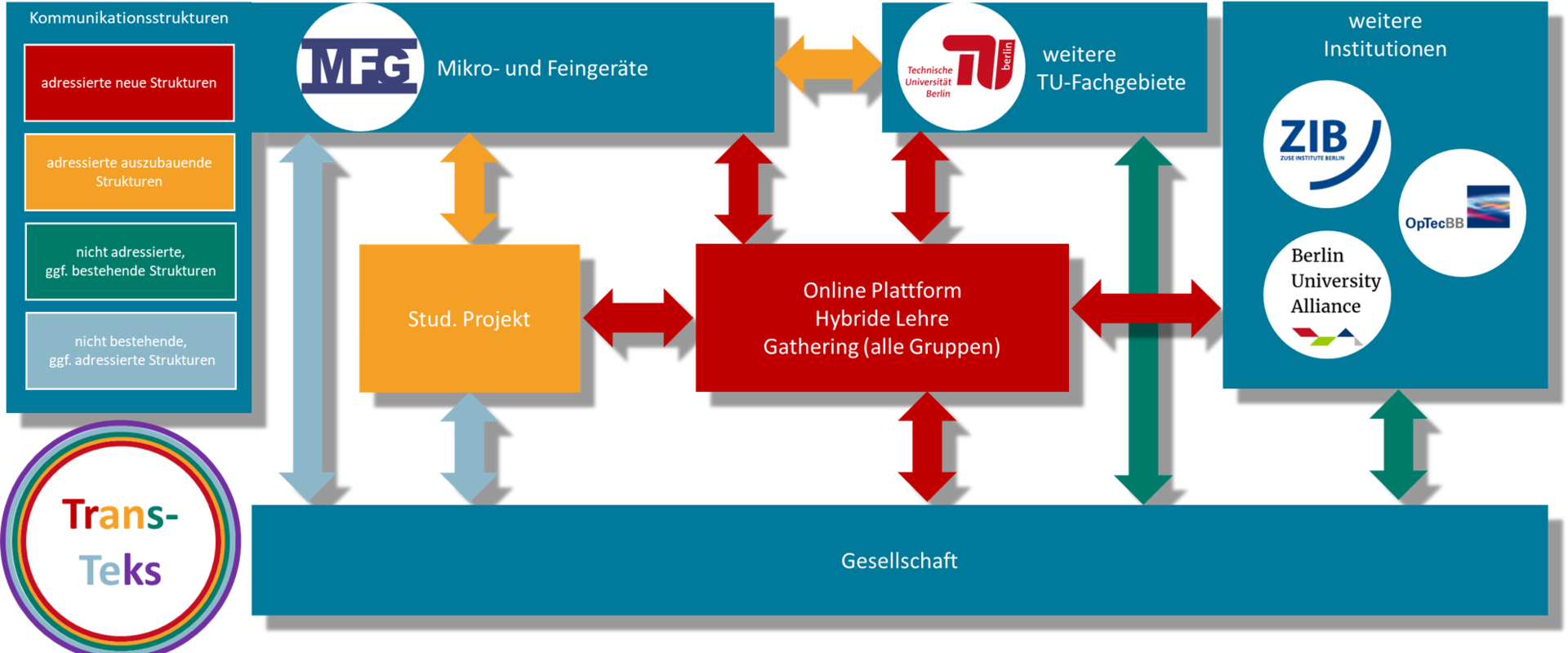

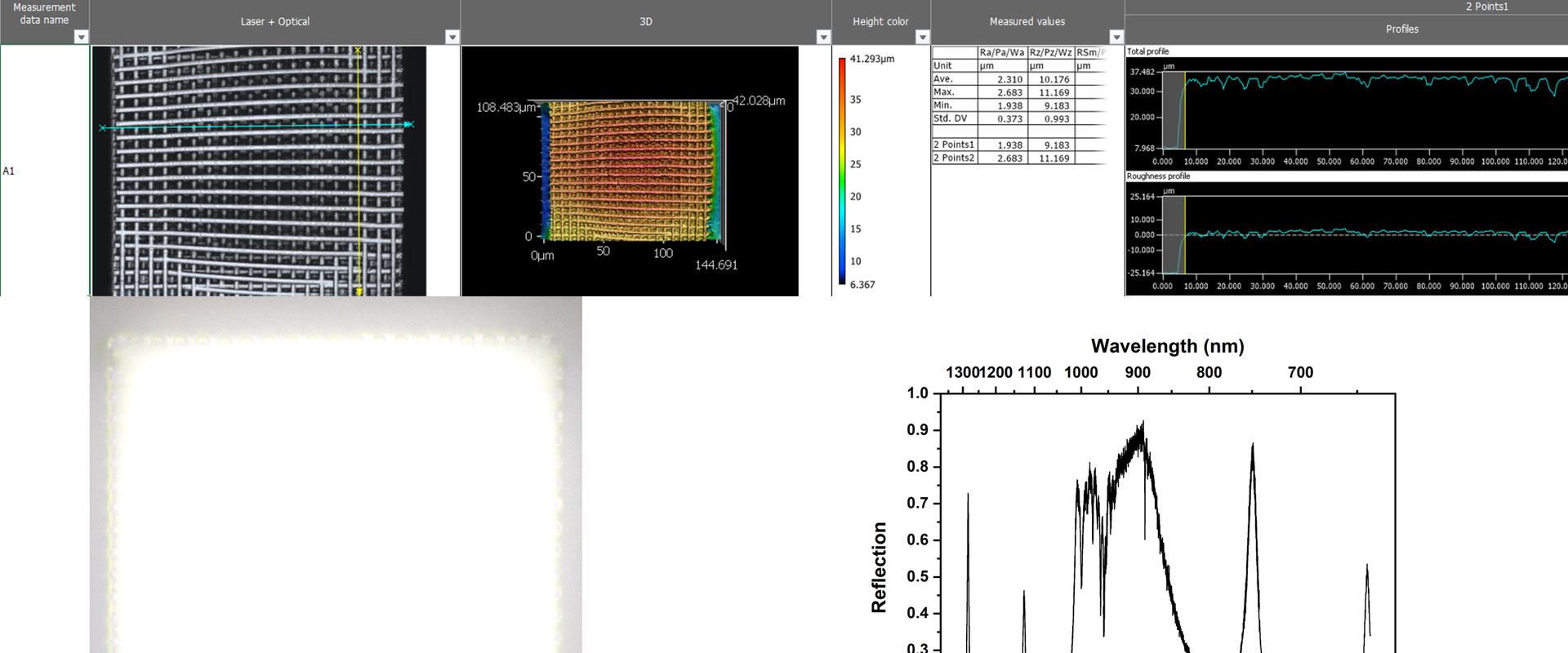

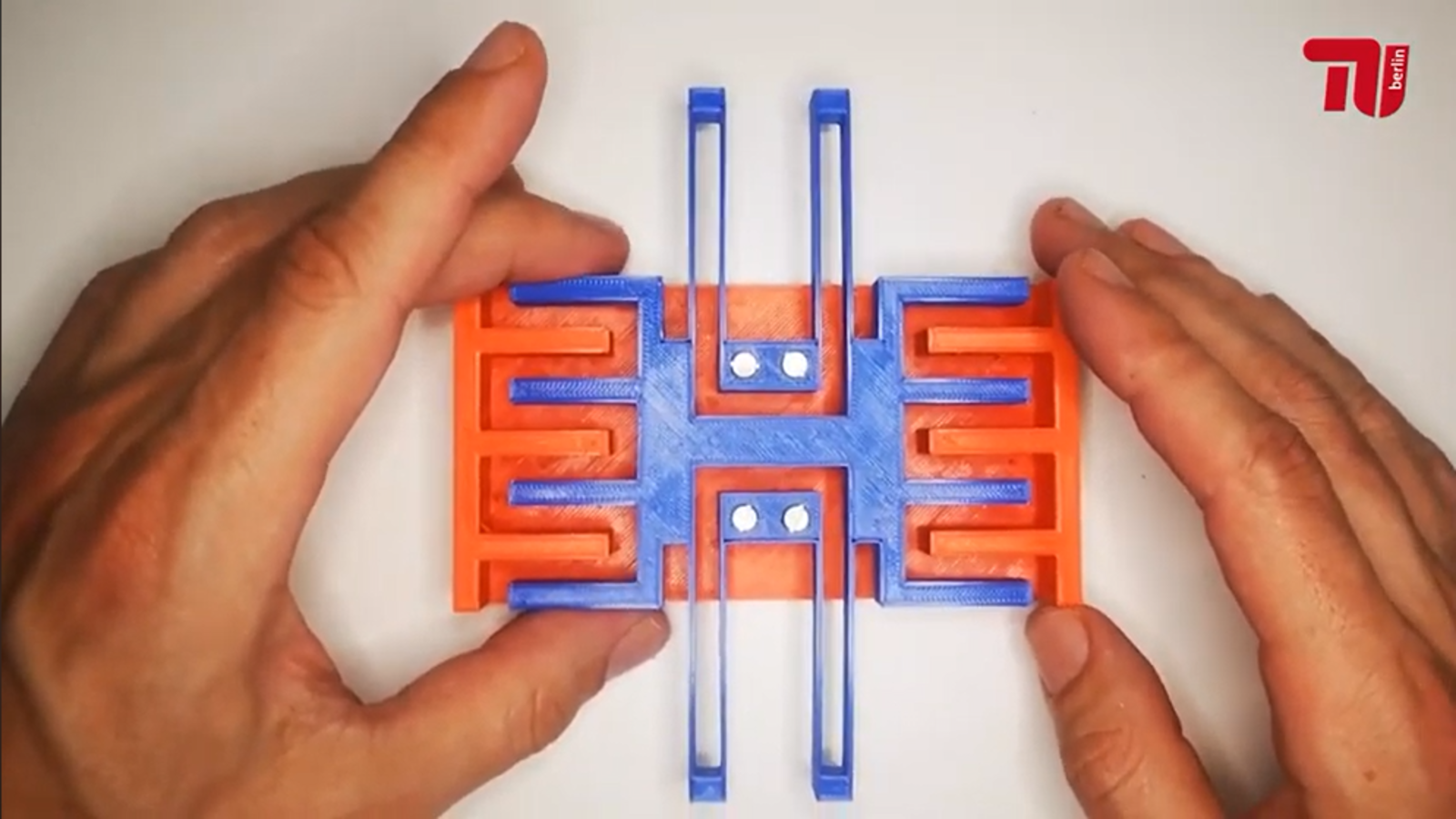

Der Fokus des Fachgebietes Mikro- und Feingeräte liegt auf der Entwicklung und Realisierung mikrooptischer, -mechanischer, -fluidischer und -elektrischer Teil- und Komplettsysteme. Hierbei umfasst unsere Forschung die Entwicklung von Produkten, Produktionsprozessen und Funktionswerkstoffen.

In der Lehre steht das Fachgebiet Mikro- und Feingeräte für die fundierte, praxisorientierte Ausbildung Studierender in den Bereichen der Mikro- und Nanotechnik.

Vorstellung: Maschinenbau-Vertiefungsrichtung Mikrotechnik

Bitte beachten Sie: Sobald Sie sich das Video ansehen, werden Informationen darüber an YouTube/Google übermittelt. Weitere Informationen dazu finden Sie unter Google Privacy.

© @ProKI-Netz

© @ProKI-Netz